Introduction

In the automotive supply chain, few things matter more than delivering reliable, safe, and compliant products. For suppliers supporting Ford Motor Company, meeting Ford’s Customer-Specific Requirements (CSRs) is essential—not only for compliance, but for maintaining sourcing eligibility and strong performance ratings.

One area that plays a central role in Ford’s expectations is the Failure Mode and Effects Analysis (FMEA). With the shift to the AIAG & VDA FMEA Handbook, many suppliers have been working to understand exactly how Ford interprets and applies the new framework.

This blog breaks down what Ford expects, where suppliers often get tripped up, how to build FMEAs that satisfy both the letter and spirit of Ford’s CSRs and how DataLyzer FMEA can help.

Why FMEAs Matter So Much to Ford

Ford has long emphasized robust, prevention-driven quality systems. FMEA is Ford’s primary tool for ensuring that suppliers:

- Understand failure mechanisms deeply

- Prevent issues before they reach production

- Apply consistent risk analysis across the supply chain

- Demonstrate clear linkage from design intent → risk analysis → controls → validation

In Ford’s view, FMEA is not paperwork; it’s a live technical analysis that must evolve with the product and process.

How Ford Interprets the AIAG & VDA FMEA Methodology

Ford requires suppliers to use the AIAG & VDA (2019) FMEA Handbook, but with important Ford-specific interpretations. These include:

- The 7-Step Approach Must Be Followed

Ford requires clear evidence of the structured approach, especially in:

- Step 2 – Structure Analysis

- Step 3 – Function Analysis

- Step 4 – Failure Analysis

These must be logically connected and technically consistent.

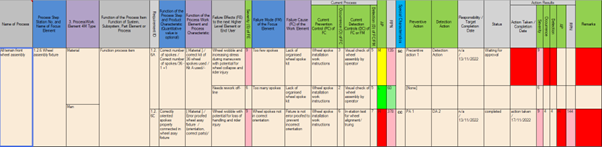

- Use of the Action Priority (AP) System

Ford expects suppliers to use AP (High/Medium/Low)—not the old RPN—to drive improvement.

- High AP items require documented action, not just justification.

- Ford auditors often ask to see closed-loop evidence that actions were taken, not simply evaluated.

- Traceability to DFMEA, PFMEA, Control Plan, and Special Characteristics

Ford places exceptional emphasis on special characteristics (SCs). DataLyzer offers an option to use a default set of symbols, or you can upload your own. Every occurrence rating, detection rating, and prevention control must clearly tie back to:

- Ford SC symbols (◊, ⌾, etc.)

- Methods of design or process control that relate directly to those symbols

- Ford Drawing & Specification requirements

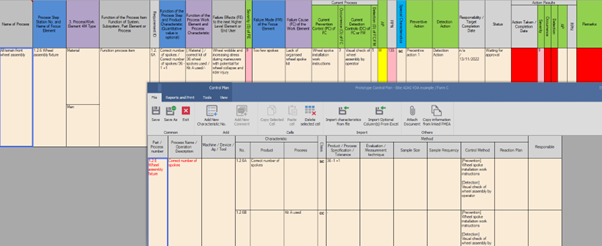

- PFMEA and Control Plan Must Be Aligned

Ford reviews PFMEA and Control Plans together, not separately. Mismatches are one of the most common audit findings. DataLyzer offer a linked Control Plan to make sure the information is always automatically aligned.

Examples of mismatches Ford flags:

- PFMEA lists a measurement method that doesn’t appear in the control plan

- Control plan lists reaction plans not supported by PFMEA detection controls

- Special characteristics missing on one document

Key Elements Ford Expects in a Supplier’s FMEA

- Technical Depth

Ford explicitly expects suppliers to document:

- Realistic failure modes (not generic ones)

- Failure mechanisms grounded in engineering knowledge

- Prevention controls that actually prevent—not just detect—issues

- Use of Current Field Data

Ford wants DFMEAs and PFMEAs informed by:

- Warranty data

- Field returns

- Past 8D or corrective actions

- Lessons learned from similar products or processes

Suppliers often fall short by failing to incorporate historical issues into new FMEAs.

- Robust “Actions Taken” Sections

Ford is stricter than many OEMs about requiring:

- Closure of actions before PPAP

- Evidence that actions reduced AP

- Technical validation data

- Clear Ownership

Ford frequently checks:

- Who updated the FMEA

- When it was updated

What triggered the update (ECN, dimensional change, process improvement, etc.)

Common Mistakes Suppliers Make — and How to Avoid Them

❌ Mistake 1: Treating the FMEA as a static PPAP deliverable

Fix: Treat it as a living document that evolves with product and process changes.

❌ Mistake 2: Using vague or generic failure modes

Ford wants mechanisms like:

“Insufficient weld penetration due to electrode misalignment”

not

“Weld failure.”

❌ Mistake 3: Misaligned DFMEA ↔ PFMEA ↔ Control Plan

This is the #1 Ford audit finding.

❌ Mistake 4: No evidence actions actually improved risk

Ford expects before/after AP ratings, updated ratings, and validation results.

❌ Mistake 5: Incorrect application of special characteristics

Ford-specific SC symbols must be used correctly and consistently.

Tips to Build Ford-Compliant FMEAs

✔ Begin with a strong boundary diagram

Ford loves boundary diagrams—especially for PFMEAs. They expect:

- Clear interfaces

- Upstream/downstream functions

- Energy sources

- Material flow

✔ Use real data to justify severity, occurrence, and detection

Unsupported ratings are one of the easiest audit findings for Ford to write.

✔ Emphasize prevention over detection

Ford’s philosophy: true quality is designed and built in, not inspected in.

✔ Show closed-loop action management

When Ford auditors ask, “Show me the evidence,” you should have:

- Updated FMEA

- Action logs

- Revised control plans

- Validation results

✔ Include cross-functional expertise

Ford expects full participation from:

- Quality

- Manufacturing

- Product engineering

- Maintenance

- Supplier quality

- Materials

- Prototype/test teams

A Quick Ford FMEA Compliance Checklist

For DFMEA

- Functions linked to requirements

- Failure modes linked to effects and SCs

- Prevention controls tied to product design

- Field/warranty issues included

For PFMEA

- Process flow + structure analysis + boundary diagrams

- Failure mechanisms linked to real process physics

- Correct SC symbols applied

- Detection controls match control plan

- Action Priority applied correctly

For Control Plans

- 100% alignment with PFMEA

- Clear reaction plans

- Verification of capability and measurement systems

Conclusion

Ford’s expectations for FMEAs are rigorous—but they are also clear, structured, and grounded in prevention. When suppliers understand the AIAG & VDA framework, incorporate Ford-specific requirements, and maintain strong alignment between FMEA documents, they not only achieve compliance—they produce better, more reliable products. Contact us to see how DataLyzer can help!

Discover how DataLyzer and our DataLyzer FMEA/Control Plan software can help you to implement Ford’s CSR. Our team of experts is ready to show you how our webbased solution can be tailored to your needs.