The Power of Statistical Process Control (SPC)

Statistical Process Control (SPC) has transformed manufacturing by monitoring and improving production processes with early detection and prevention of problems, rather than the correction of problems after they have occurred. In addition to reducing waste, SPC can lead to a reduction in the time required to produce the product and helps companies maintain consistent standards with controlled variability.

The Critical Role of Real-Time SPC:

Control charts are at the core of Statistical Process Control (SPC), giving manufacturers a clear picture of how their processes evolve over time. The goal is simple: provide insights that help quality managers step in before minor issues escalate into major ones by detecting trends, shifts, or out-of-control conditions early on. Now, imagine this: data is manually recorded by operators on paper during their shift, and once a week, an engineer transfers that data into an Excel spreadsheet to create control charts and capability indices. Sounds familiar? The problem is, by the time you notice a trend or a shift in your process, it’s too late. You might have already shipped batches with poor quality or, worse, out-of-specification characteristics, leading to unhappy customers and potential complaints. Real-time SPC changes the game. Instead of waiting, it gives you immediate feedback. A centralized database system lets you import data manually, semi-automatically with gauges, or fully automatically across the company. Control charts update every second, giving operators instant feedback and alerting engineering and quality teams to take action before a problem escalates. With this kind of real-time data, decision-making becomes faster, interventions happen on time, and quality stays consistently high.

Short Run Processes in the Context of SPC

Short-run manufacturing is all about flexibility and adaptability. It’s the type of production environment where:

- Small batches of diverse products are produced.

- Frequent setups and changeovers are required.

- Limited data points are available for each run.

Industries like aerospace, high tech and custom manufacturing often rely on short-run production to meet the demand for specialized and customized products. While traditional SPC methods excel in continuous production runs, engineers often struggle to adapt to the high variability and low data availability in short-run environments. Traditional SPC practices tell us that a control chart needs at least 125 subgroups to be statistically significant. Here’s the problem: short-run production, with its frequent changeovers and small datasets, rarely meets that requirement. This raises a critical question: How can “normal process behavior” be established when each product’s quality characteristics have such a small dataset to represent them?

Why SPC Struggles in Short-Run Production

Here are some of the key challenges that make it especially tricky implementing SPC in short-run production:

- Too Many Control Charts

In traditional SPC, every product and its quality characteristics need their own control charts. In high-mix, low-volume production, this can lead to hundreds – if not thousands – of charts. Keeping track of all that data? Operators get often confused about what’s happening on the shop floor and it’s nearly impossible for managers to effectively monitor their processes.

- Data Everywhere, Insights Nowhere

With data spread across multiple charts, it’s difficult to detect trends or small changes in the overall process. If you have only three subgroups in a chart of a quality characteristic for a specific product, how will you identify variation and trends? This fragmentation limits the ability to monitor process stability effectively.

- The Constant Hassle of Reconfiguring Charts

Every new product specification requires a new chart setup, leading to increased workload and a higher risk of errors.

- Insufficient Data, Unreliable Capability Indices

Short-run processes typically don’t generate enough data to set reliable control limits or calculate accurate capability indices like Cpk and Ppk. Without reliable metrics, decision-making turns into little more than guesswork.

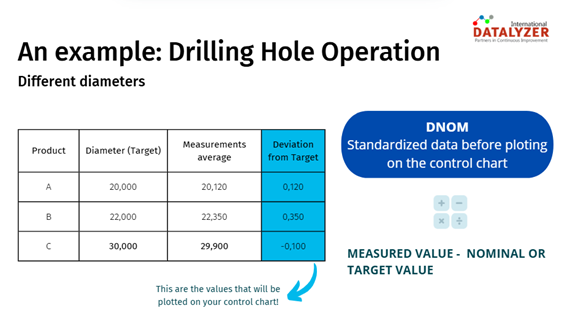

DNOM Control Charts: A Solution for Short-Run SPC

A DNOM chart represents a characteristic of interest – like weight – across multiple products, rather than focusing on the weight of one specific part. The goal is to understand how capable your process is of meeting specifications consistently. By standardizing the data before plotting, a single chart can effectively monitor the characteristic, even when the nominal values and specifications are different. The chart highlights process performance, trends, and deviations across multiple products, simplifying analysis and improving oversight.

Here’s the formula for standardizing the data:

Deviation = Measured Value − Nominal Value

Nominal value refers to the desired value found on the project design, typically set midway between the lower and upper specification limits, or tolerances. After calculating the differences for each sample, control limits can be established using conventional methods.

Advantages of DNOM

- Smarter Monitoring

DNOM charts consolidate data from multiple products into a few easy-to-manage charts, drastically reducing complexity. For engineers, this makes the process much easier to understand and navigate, empowering them to identify trends and shifts in the process without looking through hundreds of charts. With a clear, unified view of process stability, managers can make smarter, faster decisions to keep production optimized and efficient.

- Flexibility to Handle Changing Specifications

DNOM charts adapt seamlessly to varying product specifications. This means you don’t need to create a new chart for every product variation, saving time and reducing complexity.

- Time and Cost Efficiency

By simplifying chart creation and analysis, DNOM charts significantly reduce setup times. Instead of spending valuable time building and managing countless control charts, engineers and quality teams can focus their efforts on more strategic tasks.

Disadvantages of DNOM

While DNOM charts offer numerous benefits, they aren’t without their challenges. Here are a few limitations to consider:

- Theoretical Assumptions:

For accurate results, DNOM charts assume:- All products must share the same tolerance range for correct calculation of capability.

- Process variation also must be the same for control limit calculations.

- Limited Applicability Without Adaptation:

When these assumptions are not met, adjustments are necessary. While these adaptations ensure accuracy, they can also add complexity, reducing the simplicity that makes DNOM charts so appealing in the first place.

- Operator Training Requirements:

Unlike traditional charts that focus on raw measurements, DNOM charts emphasize deviations from nominal values. This shift requires operators to be trained on how to interpret the data correctly and may necessitate ongoing support to ensure proper use.

Solutions When Requirements Are Not Met

In real-life SPC applications, the goal isn’t perfection – it’s finding solutions that are efficient, smart, and practical. When the theoretical requirements of DNOM charts aren’t fully satisfied, compromises may be needed. In such situations, consider these alternative approaches to maintain process control:

- Tightest Tolerance Approach:

Use the tightest tolerance across all products for calculations. While conservative, this ensures all products meet the required standards.

- Grouping Products:

Organize products into 2–3 groups based on their tolerances or variations, then create separate DNOM charts for each group. This balances less complexity and more accuracy.

- Reduce Unnecessary Alarms:

Set a PPK benchmark- for example, a PPK value higher than 3 – and configure your system to ignore events that exceed this threshold. A Ppk greater than 3 indicates that your process is highly capable, with minimal risk of producing items outside specification. This configuration ensures your product remains within spec while reducing false alarms and preventing your inbox from being flooded with unnecessary notifications. However, keep in mind that this method might overlook subtle deviations, which could be critical in high-precision processes or when working with tight tolerances.

- Applying DVAR Charts:

To be complete we discuss another approach found in literature.

This other approach for short-run SPC is DVAR charts, which plot a standardized deviation calculated as:

DVAR = (Measured Value−Target Value) / Standard Deviation for that product

While DVAR charts are statistically correct, they face two key challenges: limited data in short runs makes estimating standard deviation for that product difficult, and operators struggle to interpret resulting values because they are completely different from the measured value. This would require extensive training and potentially leading to disengagement. From the last reason we strongly recommend not to use this solution on the shop floor because keeping the operators involved is the key to success applying SPC.

Cutting-Edge SPC Backed by Proven Expertise

Real-time SPC and solutions like DNOM charts are paving the way for smarter, more efficient production – whether you’re dealing with long production runs or the complexities of short-run manufacturing. Ready to take your SPC strategy to the next level? Contact a DataLyzer SPC specialist today to learn how a cutting-edge SPC tool like Qualis 4.0 can transform your manufacturing processes and help you stay ahead of the competition.

Discover how DataLyzer Qualis SPC can help you identify critical issues faster, streamline your quality control processes and reduce scrap and rework costs. Our team of experts is ready to show you how our web-based solution can be tailored to your specific production needs.