At DataLyzer, we recognize the transformative potential of Machine Learning (ML) in manufacturing processes. Nowadays, many organizations are inundated with vast amounts of data generated by IoT and data connectivity, yet much of this information often goes unnoticed. Engineers and operators frequently lack the time to analyze all this data for continuous improvement action plans due to the demands of daily operations.

By integrating advanced algorithms into our Statistical Process Control (SPC) software, we’re not just improving data analysis; we’re enabling real-time predictive insights that empower process experts to make informed decisions.

The Power of Predictive Analysis

SPC has been proven over the last 100 years as an extreme powerful tool to keep processes in control. In case of interaction between factors, Design of Experiments (DOE) is used to find the optimal settings of processes. But DOE is always done on a specific moment in time and processes might slightly change.

Machine learning models are more powerful than DOE and can be deployed to analyze data gathered from various stages and sources of the production process, not only off-line but also in real-time. In addition it can be used to predict quality without it being measured, if the machine learning model is accurate! This allows manufacturers to identify process disturbances and other issues swiftly, enabling operators to intervene quickly at lesser cost. With predictive analysis capabilities, DataLyzer Qualis SPC now offers immediate alerts for anomalies or outliers, ensuring that quality issues can be addressed before they escalate.

Key benefits include:

- Quick Interventions: Processes going out of control can be corrected almost instantly and possibly even fully automatically if the model is accurate.

- Root Cause Analysis: Insights derived from ML help in identifying the underlying causes of problems, enhancing overall efficiency and productivity.

- Corrective action: In case of an out of control in complex processes, process corrections can be done using machine learning.

Understanding Machine Learning

Let’s understand the added value of Machine Learning within manufacturing environments.

Machine Learning is a branch of artificial intelligence that enables systems to learn from data and improve over time without explicit programming. There are three general types of Machine Learning that can be distinguished: 1. Supervised Learning, 2. Unsupervised Learning and 3. Reinforcement Learning.

- Supervised Learning: Supervised learning involves training a model to predict outcomes using a labeled dataset, which includes both input and output parameters. This process utilizes training and validation datasets to ensure accuracy. It encompasses two main types:

-

- Classification: This approach predicts discrete categories or classes. For example, in manufacturing, classification can be used for defect detection (attribute characteristics, OK versus NOK) or for categorizing production batches based on quality grades.

- Regression: Regression predicts continuous variables, representing numerical values. In a manufacturing context, regression analysis might predict quality output results based on certain input variables. Or for example predicting machine maintenance needs based on operational hours and past performance data.

- Unsupervised Learning: Unsupervised learning is a type of ML where algorithms identify patterns and relationships within unlabeled data. This approach is particularly beneficial in manufacturing environments, where large volumes of data are generated, but predefined categories may not exist. It includes two primary techniques:

-

- Clustering: This method groups similar items based on shared characteristics. In manufacturing, clustering can be used to analyze production data and segment products with similar defect patterns. For example, if a factory produces various electronic components, clustering can help identify specific types of defects (like soldering issues or component misalignment) that frequently occur in certain product lines. By recognizing these patterns, operators and quality control teams can implement targeted corrective actions to improve product quality and reduce waste.Association Rule Learning: This technique uncovers relationships between variables within the data. In a manufacturing context, association rule learning can analyze operational data to identify associations between different production variables. For instance, it might reveal that specific machine settings or environmental conditions are often associated with higher rates of quality defects.

- Reinforcement Learning: Reinforcement Learning is a learning method that involves an ‘agent’ to interact with the environment by producing actions and discovering errors. The agent learns from these outcomes to optimize processes, improve efficiency, and reduce errors over time. By continuously adjusting its actions based on past experiences, reinforcement learning can enhance operational performance.

The Impact of Machine Learning on Continuous Improvement in Manufacturing

Manufacturing organizations are increasingly achieving results by implementing Machine Learning. In Continuous Improvement, the benefits of utilizing ML are particularly noteworthy:

-

- Improved Accuracy and Consistency: ML models excel at detecting subtle defects or patterns that human inspectors might overlook. By maintaining a consistent level of precision, these models reduce human error and bias in quality control processes.

- Faster Detection and Response: With the ability to predict and analyze data in real-time, ML can instantly identify defects or issues. This rapid detection enables quick interventions, minimizing waste and reducing costly recalls or repairs.

- Predictive Maintenance and Prevention: ML models can forecast when equipment or processes are likely to fail based on historical data. This predictive capability allows companies to take preventive measures, thereby reducing downtime and ensuring a continuous flow of high-quality production.

- Cost Efficiency: By lowering defect rates, minimizing rework, reducing frequency of quality checks, reducing destructive testing, reducing energy consumption etc etc, ML-driven data analysis can lead to significant operational cost savings. Additionally, predictive analytics can optimize maintenance schedules, preventing costly breakdowns.

- Data-Driven Insights: ML analyzes large datasets from quality control processes, uncovering trends and patterns that may not be immediately visible. These insights can inform process optimization and help identify root causes of defects, ultimately enhancing production strategies.

The Role of Predictive Analysis and Decision Trees in Quality Control

Now let’s explore the added value of the use of Decision Trees for predictive outcome analysis in addition to Statistical Process Control.

At DataLyzer, we are excited to introduce Decision Tree analysis for predicting your CTQ quality characteristics and as part of the OCAP (Out of Control Action Plan). While Statistical Process Control (SPC) typically monitors individual data trends for specific quality characteristics, many manufacturing processes involve interaction between quality inputs that collectively impact outcomes where it is difficult to correct the process in case it goes out of control.

With predictive outcome analysis using Decision Trees, we can make a model of these data streams including all interactions and show the predicted quality in a real time SPC chart. This allows us to provide accurate predictions for your CTQs, meaning you get feedback much earlier at reduced cost.

At DataLyzer, we have focused on practical implementations of these techniques for your daily quality operations. One other notable outcome is our Decision Tree analysis tool for the Out of Control Action Plan (OCAP). This machine learning algorithm predicts your CTQ characteristics based on specific quality input variables. If any input characteristic or the predicted CTQ characteristic approaches an out-of-control or out-of-spec situation, the Decision Tree tool provides actionable guidance to operators of the processes to adjust the processes and prevent these undesired scenarios from occurring.

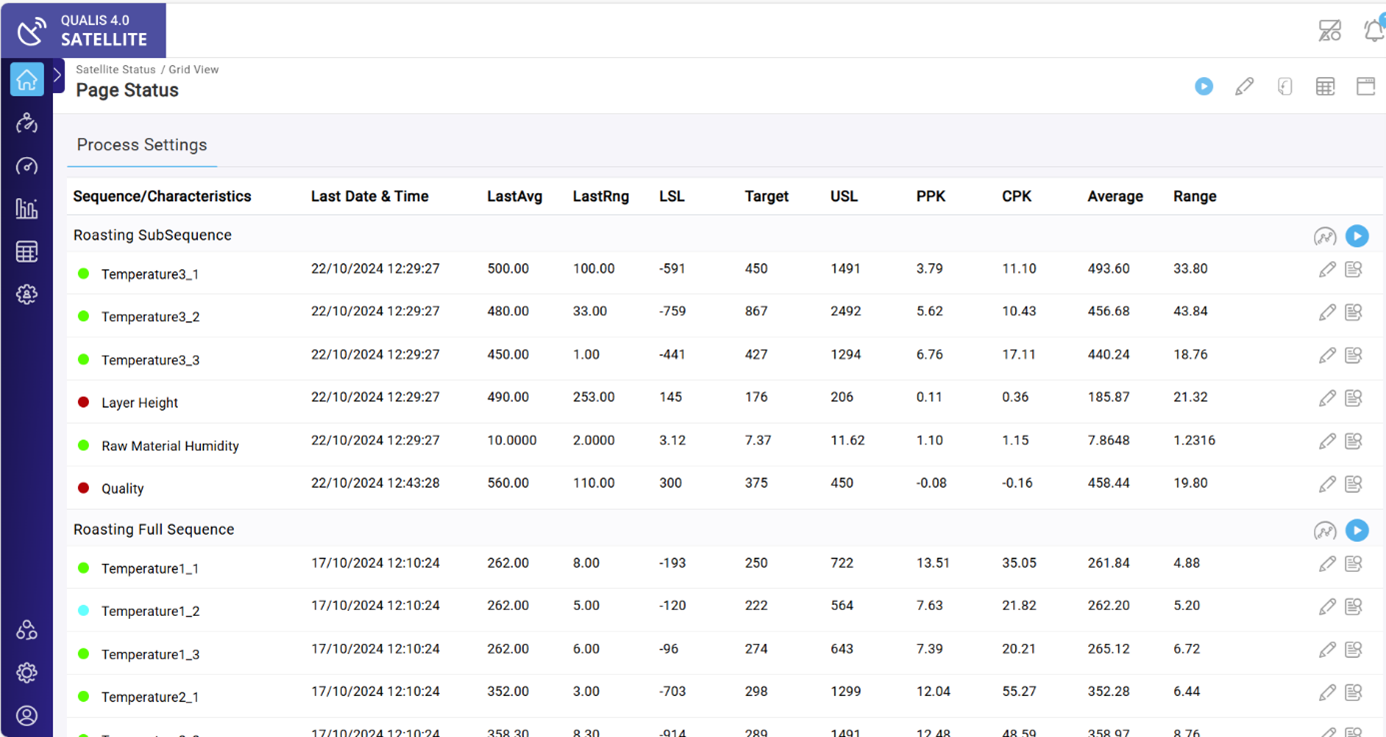

Let’s consider an example of an OCAP from a roasting process. We collect data every hour from a machine using both manual data collection and full automatic data collection from several sensors that monitor temperature, humidity, and layer height. These variables – temperature, humidity, and layer height – are critical quality input characteristics that can significantly impact the roasting outcome quality.

With DataLyzer SPC, we can automatically collect the data into our database and control these processes using a comprehensive set of SPC alarms and tools, which have demonstrated their value over the past 40 years already.

Traditionally, in case the CTQ characteristic – in this example process ‘Quality’ – goes out of control the operator needs to analyze the problem and correct the process. In case of a process with high interactions between inputs this results in a ‘trial and error’ OCAP phase.

DataLyzer Qualis SPC now supports a new OCAP feature to guide operators how to respond in such situations. This OCAP tool features a dynamic Decision Tree that directs operators to the best adjustments to make to the input variables and bring the predicted CTQ “Quality” output back in-control effectively. When the optimized settings are found, new settings will be sent immediately to the user notes to make sure all process changes are registered.

Conclusion

Start utilizing Machine Learning tools in a production environment is sometimes seen as opening Pandora’s box. However, DataLyzer offers a smooth introduction in the world of AI by integrating the most promising machine learning tools in our proven SPC solution and offering all these solutions both offline and real time.

As we move forward, a crucial factor for success in applying AI within manufacturing will be understanding the inherent risks of these models and knowing when to leverage specific technologies. To support this, DataLyzer includes data scientists in our implementation teams, ensuring you have expert guidance as you navigate the world of AI.

Discover how DataLyzer Qualis SPC can help you identify critical issues faster, streamline your quality control processes and reduce scrap and rework costs. Our team of experts is ready to show you how our web-based solution can be tailored to your specific production needs.