Measurement System Analysis for CMM Measurements

Proper Measurement System Analysis (MSA) is crucial to quality control and continuous improvement. Therefore, it is an important part within the APQP process and required by many customers and Industry Standards like Aerospace RM13000 and Automotive IATF16949.

Nowadays, many manufacturers use automatic Coordinate Measuring Machines (CMMs) to measure various product dimensions and struggle how to perform MSA studies for these measurement machines.

This blog provides advise how to perform MSA studies for your CMM machines and how you can implement an efficient MSA process within your organization using our DataLyzer Qualis 4.0 MSA Gage Management software.

Introduction to Measurement System Analysis (MSA)

Measurement System Analysis (MSA) is a fundamental aspect of quality management, ensuring the reliability and accuracy of measurement systems in various industries. Among the most widely used MSA techniques is Gage Repeatability and Reproducibility (GR&R) analysis, which evaluates the precision and consistency of measurement systems through systematic studies.

Typically, customers require their suppliers to perform MSA studies as part of their APQP project and deliverables. What studies are required depends on the customers and Industry Standards.

Gage R&R Studies can be divided into three different types of studies, Type 1, Type 2 and Type 3 studies. For CMM measurements, there is besides maybe the setup no Appraiser Variation in place and therefore, possible studies are limited to Type 1 and Type 3 studies.

The Type 1 Study is a standard requirement within both Aerospace RM13003 and Automotive IATF16949. The Type 3 Study is not part of RM13003 or IATF16949, but is part of the Automotive VDA Standard and therefore well known within the Industry for CMM and other testers with no Appraiser Variation.

Type 1 Study: Assess Gage (CMM) Repeatability

Type 1 GR&R Study is typically used to assess and understand the variation that is coming from the gage/ equipment itself only. In many organizations, the Type 1 study is even a prerequisite before doing a complete type 2 study. A Type 1 GR&R Study requires one appraiser to measure one part for at least 25 to 50 times. The part’s reference value must be included in the study as well.

As only one appraiser, the CMM machine, is involved, there will not be any appraiser influence in a Type 1 study. In another words, there will be no ‘Reproducibility’ factor in this study and the focus lies on the ‘Repeatability’ factor of the CMM.

To learn more details about the Type 1 MSA Study, refer to our prior blog: Blog: Modernizing your Gage R&R Studies with Qualis 4.0 MSA Gage Management.

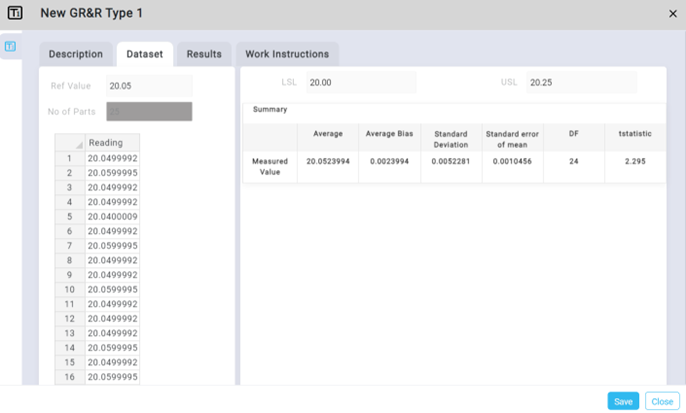

To perform the Type 1 CMM Study in our DataLyzer Qualis MSA software, the reference value, LSL and USL and the results of your CMM measurements (1 part is measured 25 to 50 times) are added to the dataset, refer to ‘Figure 1’.

Figure 1: Type 1 CMM Study Data Set

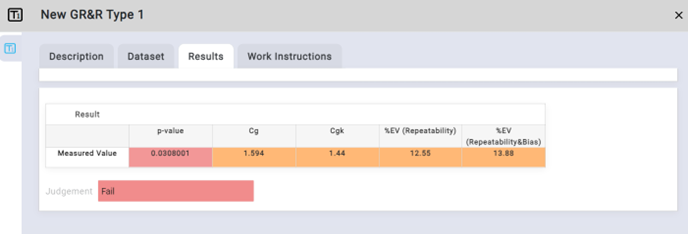

The Study Results contain the p-value, Cg, Cgk, %EV (Repeatability) and %EV(Repeatability + Bias), refer to ‘Figure 2’. Judgement Criteria for the Type 1 Study to be accepted or not can differ per Industry/ Customer Requirements, but are for example:

- P-value must be bigger than 0.05 – IATF16949

- Cg and Cgk must be bigger than 1.33 – RM13003

- %EV must be smaller than 15% – RM13003

Figure 2: Type 1 CMM Study Data Results

Type 3 Study: For CMM/ testers with no Appraiser Variation

In addition to the Type 1 Study, the Type 3 Study can be of value for your CMM MSA. This Type 3 Study is required by the Automotive VDA Standard. The Type 3 study requires 25 to 30 parts to be measured for 2 to 5 trials by 1 appraiser (the CMM). It is often criticized that for some industries within early production stages (within the PPAP) it is not possible to analyze 25 to 30 similar parts. In that case your only option is the Type 1 study.

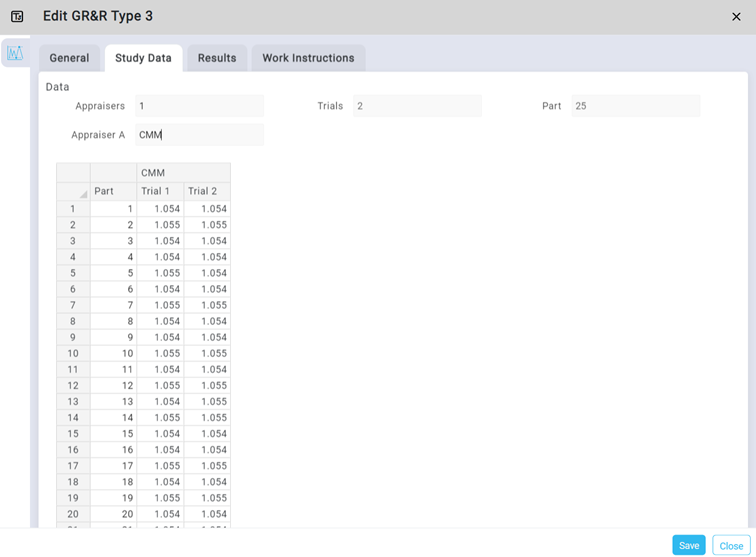

To perform the Type 3 CMM Study in our DataLyzer Qualis MSA software, the results of your CMM measurements (25-30 parts measured 2-5 times) are added to the Study Data, refer to ‘Figure 3’.

Figure 3: Type 3 CMM Study Data Set

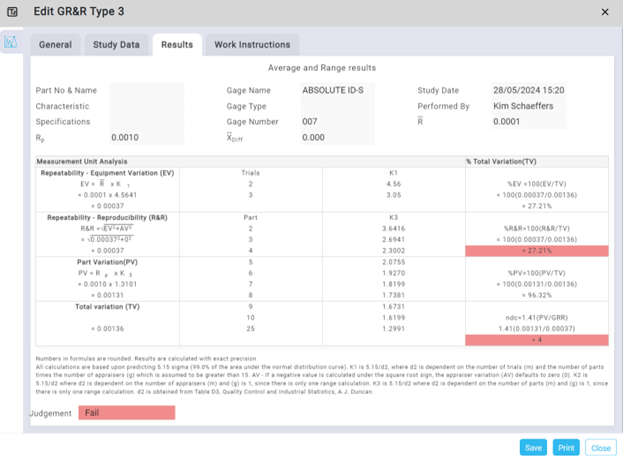

The Study Results in DataLyzer Qualis MSA can show either the Average & Range results, or the ANOVA results, refer to ‘Figure 4’ for the Average & Range Results. Judgement Criteria for the Type 3 Study are similar to the Type 2 Study Judgement Criteria but then only focus on the Equipment Variation (EV) in the calculation of the Gage R&R.

- %R&R must be smaller than 10%

- Number of distinct categories (Ndc) must be 5 or higher.

Figure 4: Type 3 Study Average & Range Data Results

And how about Type 1 and Type 3 studies for many characteristics, as typically measured within a CMM program?

Above figures show the results of MSA Gage R&R studies for single characteristic. In most cases, a CMM measurement machine measures hundreds of characteristic on a part. Currently most companies are only making a selection of the most critical characteristics because it is too time consuming to perform studies for hundreds of characteristics. In that case, DataLyzer software can be used in combination with the Automatic Import module to import all the characteristics at once and present a full MSA Type 1 or Type 3 Study. By completely automating this process you get an immediate indication which characteristics might be critical based on MSA results.

Also, companies use our DataLyzer SPC software and its reports to efficiently perform and analyze the MSA Type 1 study for the CMM. Full automatically importing MSA study measurement data into DataLyzer SPC/ control charts provides reports for Process Capability. The judgement criteria “Gage R&R should be less than 10% (or 15%)” and Cg must be bigger than 2 (or 1.33) can be ‘converted’ to a criteria that “PPI (Process Performance Index) should be bigger than 3.33 to 10”. As Cg = PPI/5.

A Gage R&R between 10 and 30% is seen as marginal and corresponds with a Gage R&R from 10 to 3.33. a PPI below 3.33 corresponds with a Gage R&R value of more than 30%.

Summary Reports in DataLyzer Qualis 4.0 SPC can report on PPI values for hundreds of characteristics based on only the CMM data output, no manual configuration needed to setup the characteristics in the database.

Discover how DataLyzer and our Qualis 4.0 MSA Gage Management software can help you to implement efficient MSA studies integrated with your CMM or other automatic measurement equipment. Our team of experts is ready to show you how our webbased solution can be tailored to your needs.