DataLyzer

Big Data & SPC integration

SPC and Big Data integration

The DataLyzer PLC/MQTT interface offers a solution to take aggregate data from OPC clients, databases or sensors and analyze subgroups in a control chart.

With the interface you can take subgroups at predefined intervals, take averages and dispersion from a predefined interval or convert large amounts of data to attribute subgroups.

In the graph below you see the data imported from the PLC signal in the figure above.

Big data and Industry 4.0/5.0

You produce materials and goods that are successful on the global market. Your business is a networked system possibly with several sites and production facilities. Over the past few decades, you have achieved a high degree of automation using the aid of digital technology and have established complex, data-processing systems that support the company’s many processes in an optimal manner.

While the company’s automation has often been divided into the areas of Automation/Control, MES, ERP and Supply Chain, these traditional classifications are increasingly breaking down. The (Industrial) Internet of Things, Big Data, Fast Data and other topics are being touted as the new providers of IT salvation. However, the wise decision is to continue the industrial evolution and use new technical possibilities to further increase the company‘s automation, transparency and efficiency.

The application of new technologies differs according to the industrial sector. For instance, manufacturers of consumer goods increasingly seek to use social networking to connect with their customers, whereas manufacturers of intermediate products strive to achieve more flexible, and consistent process automation with zero-defect manufacturing and real-time networking in the supply chain.

Common to all of these projects is the need for complete, secure and uninterrupted real-time data communication. This needs to overlap, across all production facilities, existing systems, assets and distribution points worldwide. The resultant data cloud has to bring value for each individual decision-maker in your company: at any time, at any place and on any device, while also serving as a general system integration point for any future applications.

Therefore, it is the time to break the classic organizational segments of enterprise IT and create information continuity.

Simultaneously, this closes the gap between OT and IT that was stipulated for decades by leading consultants.

Company automation in the 21st century is a seamless process. The company-wide flow of information in real time can finally unite the technologists within the company to realize considerable added value.

Big data, Machine Learning and SPC

With IoT and PLCs large amounts of data can be collected and stored or made available. AI tools come availabel to find models of the process and try to optimize the process based on the model.

We have learned from history that advanced models (like DOE) will become less useful if data entered is not in control, so ideally we check if the data used in the model is in control. Keeping the process in control has 2 large advantages:

1. The process will become more preodictable and if properly designed will provide better quality if we keep it in control

2. The data of a process in control can be used in a Machine Learning model

To integrate IoT and collect Big Data companies are using MQTT.

Attached whitepaper will explain what MQTT is and why it is a preferred method in a modern architecture to capture process and product data.

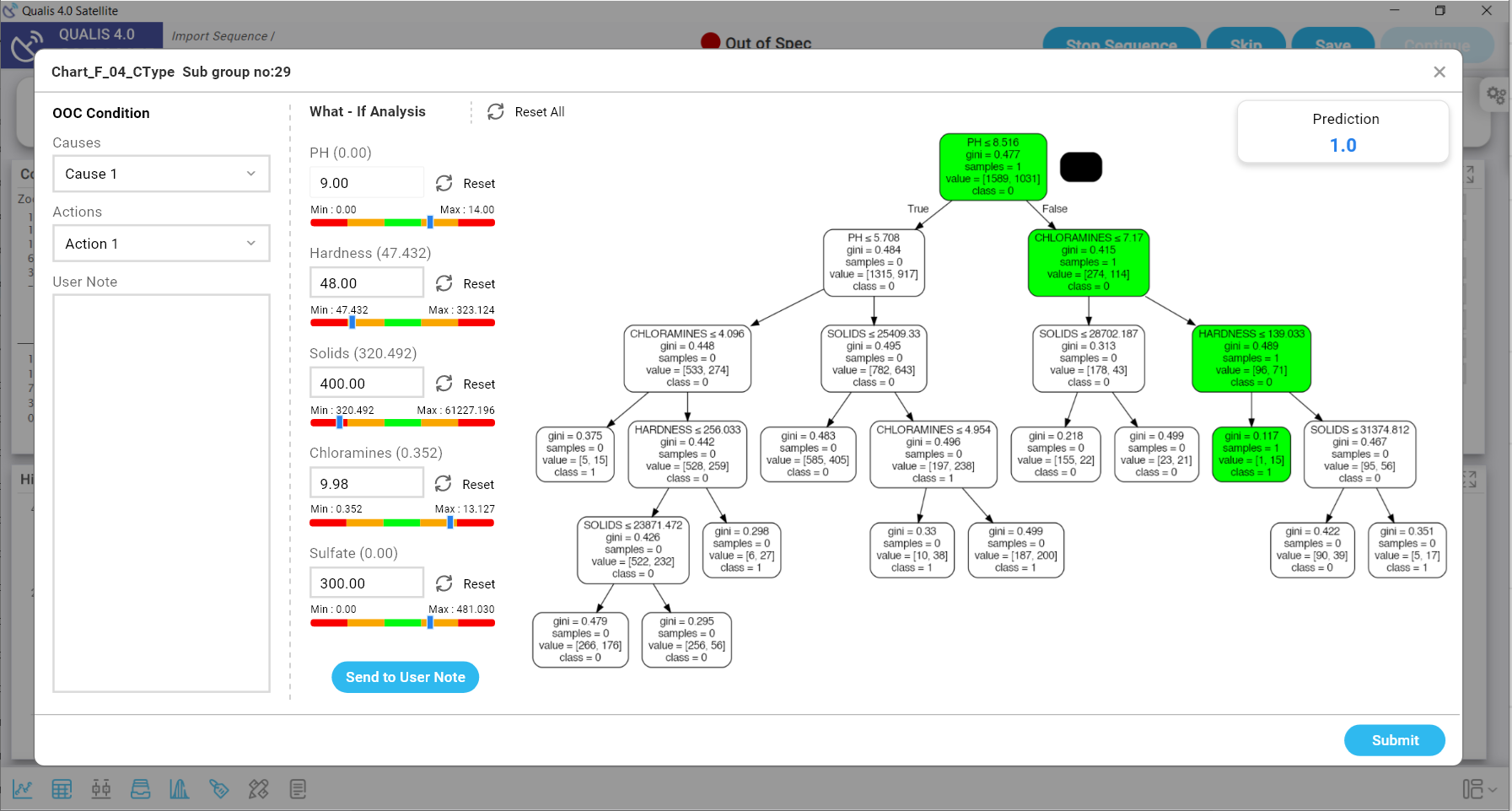

When the process is in control DataLyzer offers machine learning to analyze the data and come up with a Random Forest model to predict the output. The predicted output can even be used in a control chart to adress any probable issue at a very early stage and offer the operatorm a tool to correct the process long before scrap or production loss will occur. (See example OCAP screen with random forest tree on the left)