Why SPC Sometimes Needs More Than Points Beyond the Limits

Many quality teams rely only on points outside the limits to detect special causes. This approach finds large shifts but misses early signs of drift. Most process failures develop long before a point crosses the upper or lower limit. You protect your process when you use additional rules that read patterns over time. These patterns show how the process behaves, not only how far a single point sits from the mean. You get more warning time and more control over variation.

DataLyzer Qualis SPC uses a focused set of pattern SPC rules that support early detection without overwhelming operators with noise. These rules are based on long experience in production environments. They increase sensitivity in the right places and keep charts readable for the shop floor.

When More Detection Rules Are Required

A point outside the limits is straightforward. The process demands attention. The problem is that this signal often appears late. Consider a few common situations.

A process shifts slowly toward the upper limit. Every point stays inside the limits. Operators think the process is stable. Scrap rises in small increments.

A process forms tight clusters in a single zone. The mean moves. No point crosses the limits. The chart hides significant change. A costly example is overweight in food industry. If the overweight is small it will not be detected but running a small amount of overweight for a long time will be costly.

A process alternates between high and low points. Tooling or alignment issues introduce a cycle. The process stays inside the limits. The cycle grows until the product drifts out of tolerance.

These events show clear loss of stability. You detect them early when you watch patterns instead of single points.

Understanding Special Cause Variation

A point beyond the limits signals trouble. You already know this. The problem is that this rule alone reacts late in case of small disturbances. A process can drift for hours or days and still stay inside the limits. Operators see nothing. Supervisors see nothing. Scrap grows quietly.

Some examples:

A slow drift upward never crosses the upper limit for a long period. A long run on one side of the mean warns about this. A cluster of points near a control limit tells you the process is no longer centered. A fast jump toward the limits does not cross them but reveals instability. A pattern of alternating highs and lows shows a cycle introduced by tooling, setup issues or operator tampering.

These patterns create real signals. They show loss of control even when every point sits inside the limits.

Many studies show that pattern rules catch special causes faster than limit checks alone. They also increase false alarms when used without discipline. The real value comes from the right balance between sensitivity and noise.

Key SPC Rules in DataLyzer Qualis SPC

Quality teams need pattern detection that works with real production noise. DataLyzer focuses on rules that offer high value in practical environments. These rules monitor shifts, clusters and cycling behavior. They help you act before the process escapes control.

The rules are:

Runs

A run is a sequence of consecutive points all located on one side of the centerline. Long runs can reveal shifts in process average. DataLyzer Qualis SPC flags these so you can respond quickly. Check for changes in raw materials, personnel, equipment settings, or other process conditions.

Trends

Trends are periods where points increase or decrease in succession. DataLyzer Qualis SPC highlights these trends so you can act before the process leaves control limits. Trends often point to gradual problems like tool wear, equipment drift, or changing environmental conditions. Stopping and addressing a trend early can prevent scrap and rework.

2 of 3 in Zone A

Watch for two out of three consecutive data points in Zone A on the same side of the centerline. Zone A is the region between two and three standard deviations from the process mean. This pattern is rare in stable processes, so it serves as a strong signal of special cause variation. Investigate any outside influences, errors, or changes that might create this pattern.

3 of 7 in Zone A

This rule identifies three out of seven consecutive points falling in Zone A on the same side. It increases your sensitivity to smaller process shifts that may otherwise go unnoticed. When you see this pattern, it is time to review recent process changes, maintenance activities, or environmental factors that could be affecting performance.

4 of 10 in Zone A

If four out of ten consecutive points land in Zone A on the same side of the centerline, you have an early warning of a possible shift. This rule can help you spot trends before a process moves entirely out of control. Use it to initiate a root cause review and collect more information about your process inputs and recent changes.

4 of 5 in Zone B

Four of five consecutive points in Zone B on one side of the mean is another warning signal. Zone B lies between one and two standard deviations from the centerline. This rule targets situations where the process is moving away from its established average, but not yet to an extreme. Take time to look for incremental changes or slow drifts that could impact quality.

How to Apply These Rules in Day-to-Day Production

Start with a simple structure. Use full rule coverage for critical features and targeted rule coverage for secondary features. This keeps sensitivity where you need it and reduces noise in less sensitive areas.

Critical characteristics require fast action. These include safety features, regulatory requirements and any characteristic with strong customer impact. Apply all supported rules. Configure alerts for operators and supervisors. Define required actions.

Secondary characteristics consider the standard simplified rules to avoid over-alerting and false positives, while still catching real shifts when they start. DataLyzer Qualis supports this distinguishment because you can setup different rules per characteristic.

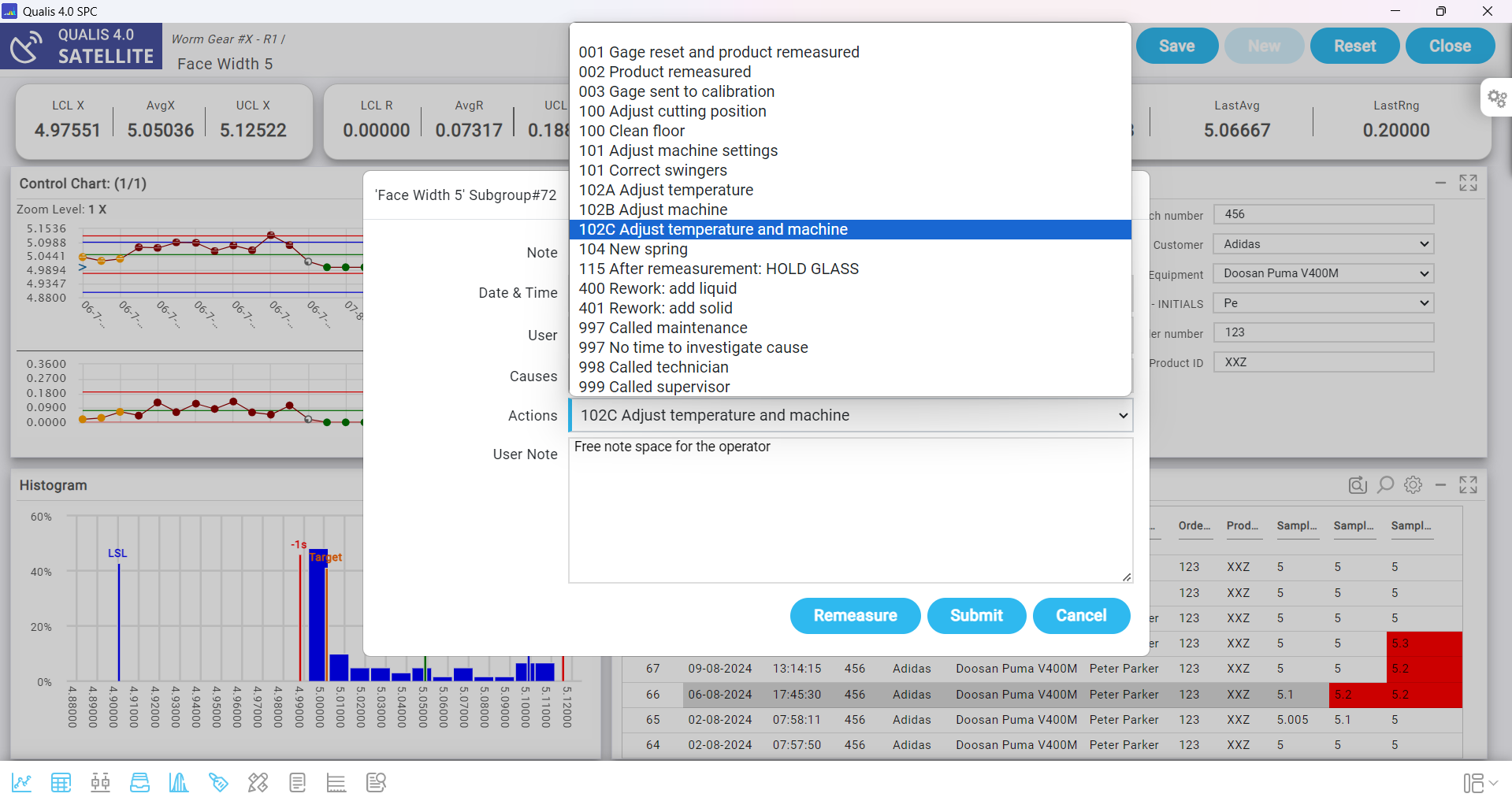

A clear response plan is essential. Operators need to know exactly what to do when a rule fires.

Define who responds.

Define the timeframe.

Define what checks to perform.

Define what to record.

Define when to escalate.

This keeps discipline high and reduces confusion. A pattern rule without action is wasted information.

How to Configure the Rules Effectively

Good configuration depends on data. Review historical behavior. Identify normal variation. Identify typical clusters. Identify common cycles. This shows the level of natural noise and helps you choose the right rule intensity.

Spotting a subtle pattern is step one. The next is to investigate and escalate with a defined protocol. Pull your team together, review what changed—materials, settings, personnel, tools, or measurement methods. Document what you find. Make sure you adjust your process or controls to shut down the issue before quality is impacted.

SPC is about continuous learning and improvement. By looking beyond simple control limit breaches and embracing these rules, you protect your process, cut costs, and serve your customers better.

Take Action, Not Chances

SPC becomes stronger when you read patterns. Points outside limits tell only part of the story. Drift, cycles, long runs and clustering reveal deeper issues. DataLyzer Qualis SPC supports targeted rules that detect these patterns without overwhelming your team. You choose the rules for each characteristic based on risk. You configure alerts for fast reaction. You monitor results. You refine the setup.

When you apply these rules consistently, SPC becomes a control tool that protects performance and improves your process every day.

Discover how DataLyzer and our Qualis 4.0 SPC software can help you to implement Statistical Process Control that works in practise. Our team of experts is ready to show you how our web-based solution can be tailored to your needs.