Introducing Digital DFMEA and Design Reliability

In today’s fast-paced product development world, every design decision carries potential risk. Whether you’re developing a new automotive component, a medical device, or an industrial machine, even small design oversights can translate into costly failures downstream. That’s where Design Failure Mode and Effects Analysis (DFMEA) comes in — not just as a compliance tool, but as a proactive strategy for building reliability and customer confidence right from the design stage.

To make this process more effective, many organizations are turning to DataLyzer, a platform designed to bring structure, traceability, and real-time collaboration into DFMEA execution. By digitizing and integrating risk analysis into a connected quality ecosystem, DataLyzer enables teams to identify design weaknesses early, collaborate efficiently, and continuously improve product reliability.

Why DFMEA Matters in Modern Design

DFMEA has long been a cornerstone of quality management. It systematically identifies potential failure modes in a product design, analyzes their causes and effects, and helps teams prioritize preventive actions before prototypes even reach the production floor.

But modern design environments are more complex than ever. Shorter development cycles, global collaboration, and tighter quality standards (like IATF 16949 and ISO 9001) have pushed organizations to rethink how DFMEA is performed. It’s no longer enough to fill out a static spreadsheet; the new expectation is living risk management — an ongoing, data-driven process that evolves alongside the design itself.

As the AIAG-VDA FMEA Handbook (2019) emphasizes, DFMEA today is about structured thinking and traceable decisions. The goal isn’t just to document potential failures, but to embed reliability into the design culture

Modern DFMEA: From Documentation to Decision-Making

Traditionally, DFMEA has relied heavily on manual tools such as Excel templates or paper-based forms. While these may work for small projects, they quickly reveal limitations in larger or more dynamic environments. Multiple engineers editing different versions of the same file can lead to confusion and data inconsistencies. Traceability between design changes, risk assessments, and control measures becomes cumbersome. And because DFMEA data often sits in isolation from downstream activities like PFMEA or Control Plan development, valuable insights rarely flow across teams.

Modern DFMEA has evolved beyond its checklist origins. The AIAG-VDA harmonized approach promotes a structured, seven-step methodology focused on function-based analysis and cross-functional collaboration. Instead of simply calculating Risk Priority Numbers (RPN), teams now prioritize actions using Action Priority (AP) — emphasizing real decision-making over documentation.

A robust DFMEA provides clear insight into:

- Where design weaknesses might occur,

- Which risks demand immediate attention, and

- How changes in materials, tolerances, or design can influence reliability.

In essence, DFMEA today acts as a bridge between innovation and assurance — enabling teams to design creatively while staying grounded in risk awareness. With DataLyzer’s digital DFMEA environment, organizations can finally execute this vision efficiently, collaboratively, and with complete traceability

How DataLyzer Transforms DFMEA into a Continuous Improvement Engine

As organizations move away from document-based risk analysis toward digital quality ecosystems, DataLyzer stands out as a platform that transforms DFMEA from a static checklist into a living, collaborative decision-making engine.

Traditional DFMEA tools often stop at risk identification — leaving teams with long action lists but little connection to what happens next. In contrast, DataLyzer integrates DFMEA seamlessly with PFMEA, Control Plans, SPC, and CAPA, creating a closed-loop quality environment where design insights continuously inform production, and real-world data feeds back into design improvement.

With DataLyzer, teams can:

- Follow a structured, AIAG-VDA-aligned workflow: Ensuring every DFMEA step — from function analysis to action prioritization — is consistent, complete, and traceable.

- Collaborate in real time: Engineers, quality teams, and managers can work together simultaneously, with version control ensuring every update is tracked and accountable.

- Link design to process and production: DFMEA insights flow directly into PFMEA and Control Plans, ensuring that preventive actions identified during design are implemented and verified on the shop floor.

- Close the loop with data feedback: Through integration with SPC and CAPA, teams can detect whether predicted risks actually occur in production and feed that information back into future DFMEA cycles.

This continuous feedback system transforms DFMEA from a one-time documentation exercise into an active learning framework. Every product release strengthens the next design iteration, turning quality into a measurable, repeatable process.

By embedding DFMEA in a connected digital ecosystem, DataLyzer ensures that risk management becomes part of the company’s DNA — supporting data-driven decisions, faster response to quality issues, and a culture of proactive improvement. Ultimately, DataLyzer doesn’t just make DFMEA easier to perform — it makes it more powerful. It connects people, processes, and data in a way that turns design reliability into a competitive advantage.

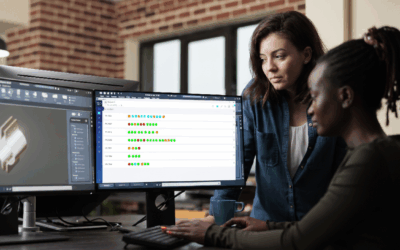

Figure 1: DFMEA in DataLyzer FMEA software

Conclusion: Designing with Confidence

Design failures are costly, but most of them are predictable — and preventable — when teams adopt a disciplined DFMEA approach. The transition from spreadsheet-based analysis to integrated, data-driven systems allows organizations to collaborate better, act faster, and design smarter.

With DataLyzer, DFMEA becomes more than a compliance tool; it becomes a central part of a company’s innovation and reliability strategy. By empowering teams to anticipate risks early and manage them effectively, DataLyzer helps manufacturers design with confidence — and deliver products that consistently exceed expectations.

Discover how DataLyzer and our Qualis 4.0 SPC software can help you to implement Statistical Process Control throughout the full factory. Our team of experts is ready to show you how our webbased solution can be tailored to your needs.