Introduction

Modern manufacturing runs on precision. Every cut, bore, and assembly is measured and recorded. Yet, in many plants, those measurements still live in silos. A CMM captures precise dimensional data for parts or assemblies. An SPC system interprets that data statistically to reveal process behavior. On their own, both are powerful. Together, they enable continuous feedback between inspection and production.

Integrating CMM data with SPC closes the loop. It lets quality engineers see trends directly from inspection results and act before products go out of tolerance. The result is less rework, fewer deviations, and a faster response to drift on the shop floor.

Why CMM-SPC Integration Matters

A shaft measured on a CMM might still be within tolerance, but SPC would show a gradual shift toward the upper limit. That trend signals tool wear or temperature drift. Without SPC, the change goes unnoticed until scrap or customer complaints appear.

When you connect the two, data moves automatically from measurement to analysis. Engineers get live visibility, not yesterday’s report. Process adjustments can be made early, and control limits stay meaningful.

Quality Digest reported that companies linking CMM and SPC reduced manual entry time by up to 80% and improved reaction speed by 60%. The payoff is measurable in both productivity and stability.

What an Effective lntegration Looks Like

A well-designed integration has several elements:

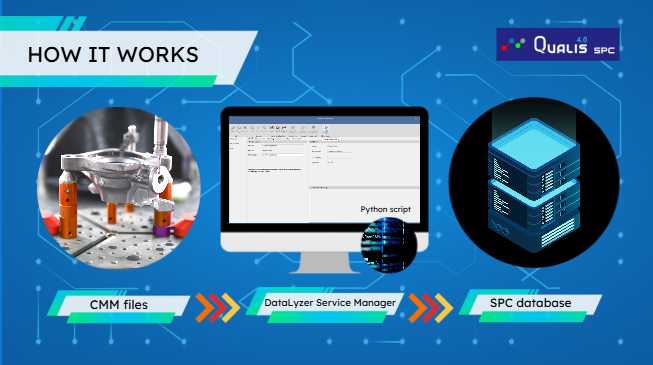

- Automatic data transfer: measurement results flow directly from the CMM output to the SPC database. No manual typing, no spreadsheets. Files or APIs handle the handoff in real time.

- Consistent format: data uses standard identifiers, such as Q-DAS tags or defined field mappings. This ensures every characteristic, tolerance, and result lines up with its SPC variable.

- Intelligent mapping: when new characteristics appear in a measurement program, the SPC system should recognize them automatically and update its records creating the respective control charts. Engineers do not have to remap features manually.

- Error handling and logging: the system tracks every file processed and flags incomplete or corrupted data. This makes troubleshooting simple and prevents silent data loss.

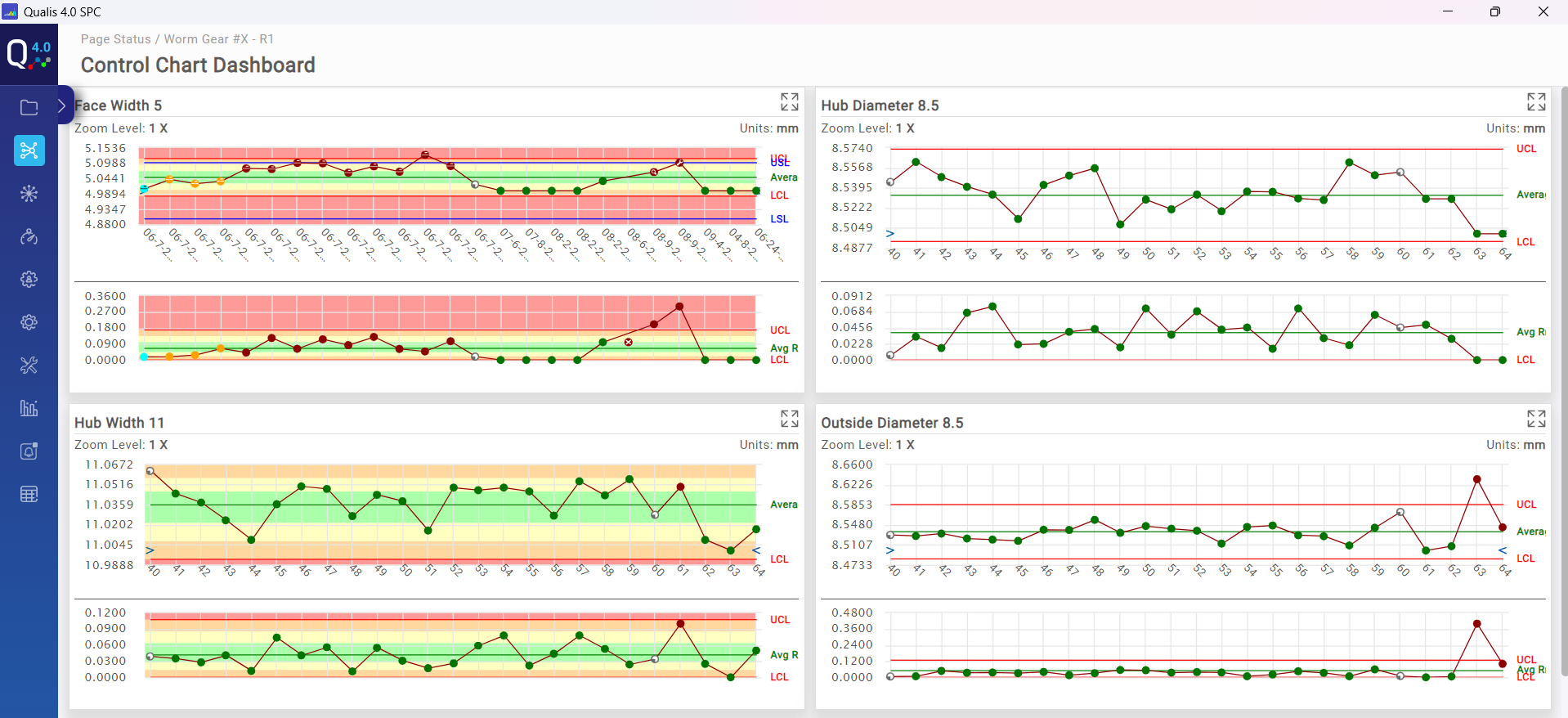

- Centralized visibility: all measurements across machines, parts, and lines converge in one SPC environment. Quality teams can filter, chart, and compare performance without jumping between systems.

- The most advanced integrations connect the SPC dashboards with the ERP system. As each production order is released, the SPC environment automatically filters and displays only the part numbers currently being produced. Operators and engineers see live control charts relevant to the active order, without manual selection. This alignment keeps dashboards accurate, reduces setup errors, and links real-time quality data directly to planned production.

Typical Challenges

Integration is rarely plug-and-play. Quality managers often face recurring challenges:

• Inconsistent data structure. CMMs frequently produce outputs in formats that vary by machine or revision. Without standardization and a structured approach, the SPC system cannot interpret values reliably. The workflow should also define error handling procedures and data validation rules to maintain integrity.

• File access conflicts. Machines sometimes write files that are still in use when the SPC system tries to read them, causing data lock issues. Effective integration planning specifies how CMM data will be captured, transmitted, and synchronized with the SPC database. It requires mapping measurement points, establishing data collection intervals, and communication protocols between CMM hardware and SPC software.

• Limited flexibility. Some SPC systems restrict compatibility to a single CMM vendor or file type. When multiple brands operate on the same shop floor, the integration becomes unstable and difficult to maintain.

Overcoming these barriers demands a structured approach and a mindset that treats data flow as a core process, not an afterthought.

Story: When a CMM Meets Real-Time SPC

A global automotive supplier once ran into a bottleneck. Their metrology lab used a Hexagon CMM to inspect high-precision components every hour. Results were exported as Q-DAS DFQ files, then manually uploaded to an Excel spreadsheet weekly. By then, several production batches were already completed.

Operators were frustrated. They followed the process, but by the time quality engineers saw trends, it was too late to adjust. The team wanted live SPC feedback but wanted to avoid constant manual updates, costing them a lot of time.

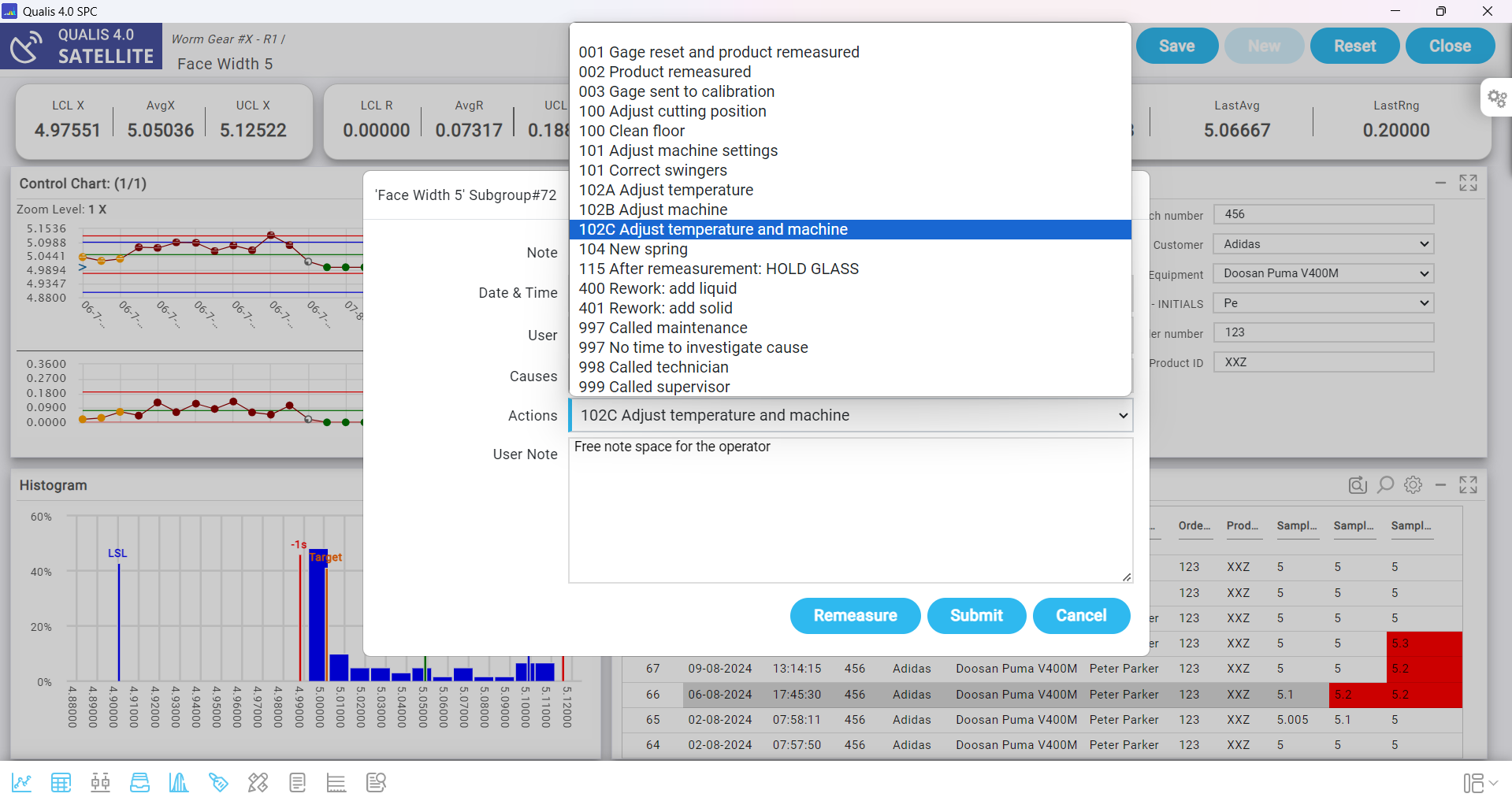

The company partnered with DataLyzer to automate the flow. A CMM importer was implemented that monitored a shared folder where CMM results were saved. Each time the CMM completed a measurement, the adaptor validated the DFQ file, extracted the values, mapped them to the correct parts and characteristics, and transferred them into the SPC database. Invalid files were moved to a separate folder and flagged for review.

Once the integration was live, automated emails were triggered for key SPC events. When an out-of-control (OOC), out-of-spec (OOS), or statistical trend was detected, the system sent alerts directly to predefined recipients. The operator had instant feedback and asked to input the causes and actions taken comments. Specific parts or critical characteristics could be configured to notify only certain engineers or supervisors. This selective routing kept communication precise and reduced noise.

Within a few days, the integration was running 24/7. The SPC dashboards refreshed automatically as new CMM results arrived. Engineers no longer waited until the end of the shift to act. When a bore diameter began trending upward, the SPC chart triggered an alert before any part went out of spec. Maintenance could confirm tool wear and replaced the insert before scrap occurred.

No code adjustments were needed on the CMM side. No extra work for operators. The inspection team kept using the same measurement routine. What changed was the timing: data now reached decision-makers instantly.

This single improvement reduced dimensional nonconformities and cut lab reporting time. More importantly, it built trust between production and quality. Everyone saw the same data, in real time.

Lessons from the Field

- Keep it simple at first. Start with one CMM, selected parts, and a few critical dimensions. Once stable, scale to more machines.

- Automate folder importing. A small service or adaptor can watch for new measurement files and push them into SPC as soon as they appear.

- Validate data before import. Check for completeness and correct tags. Reject or quarantine invalid files automatically.

- Separate environments. Use distinct folders for source, archive, and invalid data. This prevents duplication and ensures traceability.

- Document rules. Define mapping tables, naming conventions, and version control for all data exchange points.

- Assign ownership. One engineer or team must be responsible for maintaining the integration.

These practices keep the connection robust and predictable, even when programs or machines change.

Future Trends in CMM and SPC Integration: Artificial Intelligence

Advancements in technology drive improvements in precision measurement and statistical process control. Enhanced automation, intelligent data processing, and modern data management practices are shaping the way manufacturing quality is maintained and optimized.

Machine learning algorithms analyze measurement and process data to identify correlations such as process settings, tool wear or part deviations early, enabling proactive preventive actions.

Artificial intelligence supports adaptive control of manufacturing processes by using predictive analytics. This reduces scrap rates and enhances process stability because feedback loops act in real time based on CMM measurements.

Results You Can Expect

Plants that connect CMMs with SPC often report the following improvements:

- Shorter reaction times to variation

- Reduction in manual entry errors

- Stronger correlation between process and inspection data

- Fewer customer complaints and recalls due to dimensional issues

- Easier compliance with audit and traceability standards

Cloud-Based Data Management with Qualis SPC

Cloud platforms like Qualis SPC centralize CMM and SPC data, allowing real-time access across plants and departments.

Data stored in the cloud can be expanded with traceability features such as serial numbers, operator info, or machine IDs, improving audit readiness. Integration via cloud services also facilitates more straightforward software updates and scalability of data storage.

The cloud enables enhanced collaboration between design, manufacturing, and quality teams by providing a single source of truth. This reduces communication delays and ensures all stakeholders work from consistent data.

Moving Forward

Most factories already have the data they need to control variation. What they lack is connection. Once CMM data feeds your SPC system in real time, you no longer inspect quality after the fact. You monitor it as it happens. This visibility changes how teams respond, plan, and maintain capability. Every alert becomes an opportunity to improve. Plants that close this loop achieve stable processes, faster containment, and fewer surprises in production.

Watch our new video to learn how DataLyzer Qualis connects CMM measurement results to real-time SPC analysis.

Discover how DataLyzer and our Qualis 4.0 SPC software can help you to implement Statistical Process Control that works in practise. Our team of experts is ready to show you how our web-based solution can be tailored to your needs.