Introduction

The future of SPC software should be discussed in relation to the manufacturing environment in which SPC software is used and that the manufacturing environment is currently heavily influenced by the developments related to industry 4.0. In this article we will discuss what the required functionality of future SPC software is and what DataLyzer has done to comply with these requirements.

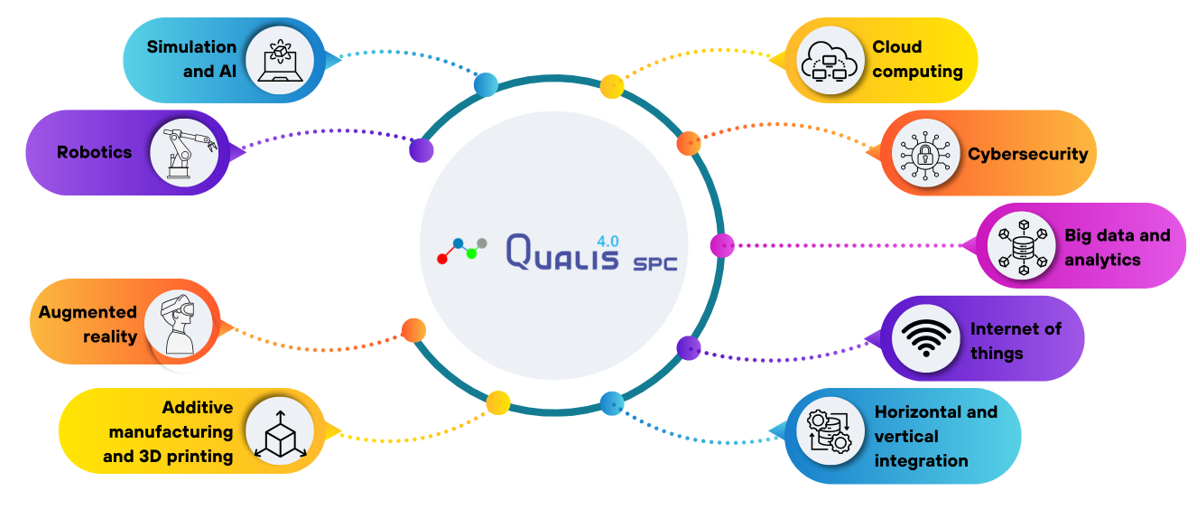

Key components in Industry 4.0 are given in below image.

Additive manufacturing, augmented reality and robotics are not directly related to SPC software, but all other components have some kind of relation with SPC software, and we will discuss them in this article.

Cloud computing

Cloud computing is a cornerstone of Industry 4.0, enabling the seamless integration of advanced technologies like IoT, AI and Big Data Analytics into industrial operations. It provides the scalable infrastructure necessary to manage and analyze vast amounts of data generated by interconnected devices and sensors in real time. This facilitates predictive maintenance, optimized production processes and data-driven decision-making enhancing operational efficiency and reducing downtime. Moreover, cloud solutions support global collaboration by offering centralized platforms for accessing, sharing and analyzing data across geographically dispersed teams. By lowering IT infrastructure costs and providing unparalleled agility, cloud computing empowers businesses to innovate rapidly, adapt to market changes and remain competitive in the era of smart manufacturing.

More and more systems like MES, ERP and Scada etc are offered as a cloud solution. We also see more and more integration between these systems using web APIs.

The complete cloud-based architecture in a company can become quite complex. To keep it possible to manage such a complex architecture web-based software programs should be developed in containers. In cloud-based computing a container is a lightweight, standalone and portable part of a software package that includes everything needed to run that part of the application, such as the code, runtime, libraries and system tools. Containers operate in isolated environments ensuring consistency across different computing environments from development to testing to production. Unlike traditional virtual machines, containers share the host system’s operating system kernel, making them faster to start and more resource efficient. This makes them ideal for cloud deployments as they enable developers to build, deploy and scale applications seamlessly across various cloud platforms while maintaining reliability and performance. Tools like Docker and Kubernetes are commonly used for containerization and orchestration in cloud computing.

DataLyzer Qualis 4.0 is fully developed in Dot Net Core and supports containerization and can be made available in a docker. The solution supports both public and private cloud solutions.

Cybersecurity

Cybersecurity in relation to cloud computing for Industry 4.0 is a critical concern as the integration of cloud-based solutions and interconnected systems exposes industrial environments to new vulnerabilities. Industry 4.0 relies on real-time data exchange, remote access and IoT devices, all of which create potential entry points for cyberattacks.

In this context, cloud providers implement robust security measures, such as encryption, multi-factor authentication and continuous monitoring to protect data integrity, confidentiality and availability. However, businesses must adopt a shared responsibility model ensuring secure configurations, regular patching and user access controls on their end.

In practice we see that it means that access to the SPC software should be based on the existing security policies in a company like SAML. In Industry 4.0 where numerous applications and services interact in cloud ecosystems, SAML ensures secure user authentication and data exchange between platforms. For example, factory systems connected to a cloud platform can use SAML to verify user credentials securely.

Other protocols such as OAuth, OpenID Connect and Kerberos complement SAML by providing different mechanisms for secure authentication and authorization, further strengthening an organization’s cybersecurity posture.

DataLyzer Qualis 4.0 supports most commonly used protocols like SAML and OKTA and the list of supported protocols is expanding continuously.

Industrial Internet of things (IIoT)

IIoT (Industrial Internet of Things) in relation to the use of SPC software refers to the integration of smart devices, sensors and connected systems into industrial processes to enhance quality control and decision-making.

- Real-Time Data Collection:

IIoT devices such as sensors and edge devices continuously monitor production lines and equipment capturing real-time data on product and process characteristics like weight, temperature and pressure etc. SPC software uses this data to identify trends, variations and potential issues before they lead to defects. - Enhanced Process Monitoring:

The combination of IIoT and SPC ensures comprehensive visibility into manufacturing processes. IIoT streams high-resolution data to SPC software allowing operators to detect anomalies faster and improve process stability.

In practice there are many different IIoT platforms and real-time high-volume data like temperatures are not always suitable to plot directly into a control chart. DataLyzer Qualis 4.0 offers a flexible import service to collect data from virtually any source, convert the data into useful SPC information by aggregating the data and then presenting the data in a meaningful control chart.

Besides sensors there is still a large part of data coming in through special measurement equipment like cameras, CMMs or databases or even simple interface solutions like ASCII files or csv files. The flexible import service of DataLyzer can also read all these sources and even automatically create the SPC configuration.

Horizontal and Vertical integration

Horizontal integration

More and more industries are adopting the APQP process. In the APQP process there is a logical flow of information from design through drawing to FMEA, Control Plan, First Article inspection and SPC and COAs.

DataLyzer offers a complete solution for the full APQP flow from automatic ballooning of drawings, creating the configuration of the SPC based on a drawing, a full FMEA solution and automatic import of measurement data for First Article Inspection reports or SPC. All data can be exported again in many ways including COAs. So, the SPC solution is embedded in a horizontal integrated solution.

Vertical integration

Vertical integration can be looked at in 2 different ways:

- Vertical integration in the IT structure

- Vertical integration in the organization

Vertical integration in the IT structure and in the context of Industry 4.0 refers to the seamless integration of processes, systems and data across different levels of an organization—ranging from the factory floor to executive decision-making. It is crucial for achieving smart, interconnected manufacturing environments.

Statistical Process Control (SPC) software plays a significant role in this integration by enabling real-time data collection, analysis and feedback loops from production processes. In an Industry 4.0 framework SPC software can integrate with IoT devices, sensors and enterprise systems (like ERP and MES) to provide actionable insights and automated quality control.

This alignment ensures that quality metrics are not siloed but are part of a broader, connected ecosystem allowing for predictive analytics, reduced waste and improved efficiency. By leveraging vertical integration SPC software becomes a cornerstone for achieving smart manufacturing goals, aligning operational performance with strategic objectives.

DataLyzer Qualis 4.0 supports this vertical integration by providing flexible interface options like a fully functional DLL, web Apis or even offer the option to run Qualis containers directly in other web-based systems. For example, you can start a Qualis inspection plan directly from a web based MES system and the end user is not even aware he or she is working in Qualis.

Vertical integration in the organization means the same SPC system is directly supporting the operator as well as the team leader, the engineer and the manager.

This means the SPC software needs to go beyond visualizing a control chart. Automatic alerts, open action screens, dashboards, OCAP procedures with buy off and summary reports should all be part of the SPC software solution. All data and functionality should only be accessible if the specific user is authorized.

DataLyzer Qualis offers many functions to support vertical integration. All requirements described above are available and with a highly granular authorization structure it can be suited to provide the right information and functionality to the right people even across multiple locations in multiple languages.

Big data, analytics and AI

As mentioned before big data cannot really be used to store directly into an SPC system so we see 2 approaches in practice:

-

- Data is aggregated and converted to provide meaningful information in control charts

- The original data is used in advanced analysis (Big Data or AI).

The first option is already described before but to support the second option DataLyzer offers a way to use data from any source during analysis without the need to import that data into the SPC database. This extra Qualis feature called Qualis Wizard can load data from any source including DataLyzer SPC data, relate the data through a common denominator like serial number, lot number or date and time and provide all kinds of different analysis options including AI in the form of random forest decision trees and text analysis.

This offers a wealth of flexibility and the option to quickly analyze data without the need to first create an import tool.

Simulation and AI

Traditionally SPC is often applied on the quality characteristics of the product. Industries more advanced with the application of SPC are also applying SPC on process characteristics. With the growth of IIoT we see more applications of SPC in process areas.

What companies try to achieve is establishing the relation between process inputs, process characteristics and product characteristics because controlling process characteristics is faster and cheaper than controlling product characteristics. A well-known technique in this area is experimental design. Now with the potential of AI new possibilities appear. Instead of performing DOE studies we can use machine learning to establish the model, and this can even be done completely in real time.

Machine learning has proven to be more powerful than DOE and can also be adjusted in real time based on changing circumstances such as tool ware and changes in material etc.

Machine learning can now be used in 2 ways:

-

- We can use machine learning to simulate the effect of a process change in case of an out of control or out of spec situation.

- We can use machine learning to predict the result of a critical process characteristic even before it can be measured.

DataLyzer Qualis 4.0 offers machine learning during real time data entry. Results can be predicted using machine learning and machine learning can also be used during process changes to simulate the effect of the change.

Discover how DataLyzer Qualis SPC can help you identify critical issues faster, streamline your quality control processes and reduce scrap and rework costs. Our team of experts is ready to show you how our web-based solution can be tailored to your specific production needs.